An Overview of Modern Pipeline Construction Techniques

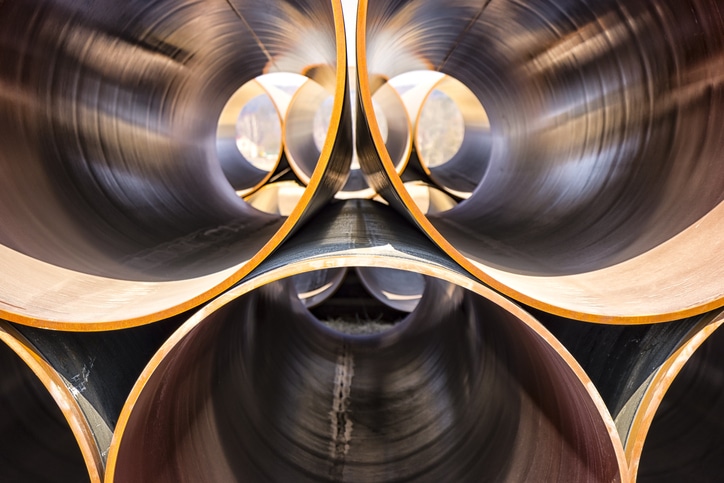

Nations all across the globe are starting to shift from traditional energy production (coal and non-renewable-based) to renewable energy production, which has resulted in a pipeline construction boom. New lines are becoming necessary for water and gas providers as more reliable materials are being introduced.

Today, we will go over the process of pipeline construction, specifically gas pipelines. We are choosing gas pipelines because it is one of the most crucial infrastructural lines, and like water, requires extra precautions. All other pipelines follow a relatively similar procedure.

Pipeline Construction Process – A Step-By-Step Overview

The first thing utility service providers need to do for pipeline or other utility construction companies is to get federal and state-level permits. At this point, any easement agreements or domain issues are also dealt with. The boundaries of the entire pipeline are marked with flags to help the public identify potential construction sites.

If needed, temporary roads and pathways are also constructed for heavy machinery.

The Construction Begins

Once approved, everything is cleared along with the construction site, and the machinery is brought up. A storage area is determined where the necessary equipment is stockpiled. These include:

- Pipes

- Fuel tanks

- Sandbags

- Silt fencing

- Stakes

- Flags

- Parking area for trucks and employee vehicles

- Office trailers

- And other equipment and parts.

The Cutting

The equipment is assembled, and the cutting begins. Any trees in the area need to be cut, and the material is either hauled off or stockpiled. The landowners are compensated. Stumps are either burned or pulled out, as necessary.

The Excavating

Once clear, the trenching begins. There are several trenching options available with respect to the pipe size and type of utility. These include:

Pipe Transport & Installation

Once the trench is completed, the pipe segments are pre-coated, and the trenches are cleared of any debris. If needed, the trenches are also coated to minimize disruptions to and from the environment. The pies are laid above-ground first (next to the trench) if they are being laid manually.

Americom uses the Fast Fusion technique, where the pipes are welded together with a self-propelled 18,750 lb machine and laid directly in the trench on top of supportive sandbags (where needed). The machine bends the pipes automatically according to the terrain.

As the pipe is laid, the sections are sandblasted, and the welded joints are coated with epoxy to prevent corrosion. Another machine (handheld in most instances) uses an x-ray scanner to ensure that all the welds are shut properly.

Testing

And finally, the pipe is inspected after being laid, and the pipeline integrity is verified. To do this, the gas is filled in the pipe in sections with sensors to make sure the pipeline isn’t leaking. The pressure is increased to the maximum operational level to stress-test the pipeline. After this, the surface is leveled and made ready for use.

If you would like to learn more about Americom’s pipeline construction or maintenance or want to schedule a consultation, give us a call!